- Metal Building Materials[1]

- Steel Wire Mesh[1]

- Other Accessories & Parts[2]

- Screen Protectors[8]

- Velcro Tapes[6]

- Protective & Cushioning Material[8]

- Insulation Materials & Elements[10]

- Other Rubber Products[4]

- Adhesive Tape[10]

- Copper Strips[1]

- Aluminum Foil[3]

- Other Electronic Accessories[2]

- Electrical Contacts and Contact Materials[1]

- Sponge[3]

- Mats & Pads[3]

- Machining Services[7]

- Gaskets[5]

- Contact Person : Ms. Deng Sunny

- Company Name : Dongguan Nanyang Electronics Technology Co., Ltd.

- Tel : 86-769-85392485

- Fax : 86-769-85395684

- Address : Guangdong,Dongguan,No.3 Industral zone, Xiagang Community, Chang'an Town

- Country/Region : China

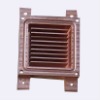

house appliance prototype

Rapid Prototype

Are you looking for high-quality, precision-engineered CNC metal models or mock ups of parts and components for your products? Please do not hesitate to contact us. Dongguan Nanyang Electronic Technology Co.,ltd.

With sophisticated CNC equipment and skilled technicians, we can, within just 3--4 dyas, craft highly accurate and realistic CNC prototype for you basing on your detailed specifications.

| Item name: | Rapid Prototype |

| Certificate | ISO 9001:2008 Certificate |

| Service Range: | 1. Rapid Prototyping; sla/sls prototype |

| 2. CNC machining prototype | |

| 3. Industrial Design | |

| 4. Silicone mould; injection molding; resin mold and vacuum casting | |

| 5. Batching production | |

| 6. Reverse engineering | |

| 7. Brass/aluminum parts CNC machining | |

| Preferred Formats: | Pro/E, Solidworks, Unigraphics, Catia, Auto CAD, *.igs, *.stp, *.stl, *.x-t |

| Surface treatments: | Paint, polish, silk-print, anodize, transparent surface, translucent surface, brush, rubber oil, electroplat |

| Materials: | ABS, Polycarbonate (PC), polypropylene (PP), Polymethyl Methacrylate (PMMA), Polyethylene (PE), Polyoxymethylene (POM), polyamide (PA), Nylon, Polyurethane (PU), , Aluminum, Brass, Easy-cut-steel and etc. |

| Industry Range | 1.Consumer electronics: Digital camera, mp3 player, television, calculators, GPS electronics, DVD/VCD player and etc. |

| 2.Medical devices: B Ultrasound scanner case, Ultrasonic diagnostic imaging care, and etc. | |

| 3.Telecommunications: micro phone, speaker, monitor case, computer and etc. | |

| 4.Auto parts: dashboard, car lamp, bar, car door, motorcycle, scooter, bike and etc. | |

| 5.Household appliance: Cooker, air conditioner, TV, fan, shower, fridge, coffee machine and etc. | |

| 6.Others: customer made, toys, exhibition samples, testing samples. |

Prototype methods:

CNC/ SLA/ SLS rapid prototype

*CNC rapid prototype.

1) CNC machining for most type-cases and components2) Laser cutting and welding for complicated and large-size sheet metal components3) Sheet metal forming for complicated and large-size sheet metal components4) Lathe for standoff, pin and shaft parts5) Die-casting for small batches

*Stereo lithography Prototype, SLA Prototyping

**Stereo lithography is the heart of ProtoCAM's rapid prototyping service, turning 3D CAD file into a solid object. Stereo lithography prototypes can be used as master patterns for injection molding core and cavity inserts, thermoforming, blow molding, and various metal casting processes.

**Key benefits of Stereo lithography Rapid Prototyping

1)Time savings: it can fabricate your SLA prototype

2)Cost savings: prices stereo lithography prototypes competitively

3)Tight tolerances

4)Epoxy resin is resilient enough to be used for testing

5)Stereo lithography is well suited to small lot manufacturing of prototype or end-use parts

6)Stereo lithography investment casting patterns allow rapid production of metal prototypes

7)Rapid prototyping allows you to get your products to market faster

*Selective Laser Sintering (SLS), SLS Prototype

Selective Laser Sintering (SLS) is a process which creates 3D SLS prototypes by fusing or sintering powdered thermoplastic materials or metals to form functional prototypes. ProtoCAM is a premier selective laser sintering service bureau.

An advantage to using SLS is the range of materials that can be used, including nylon, metals, and elastomers.

Rapid prototype (RP) laser sintering can provide a competitive edge in your product development by

producing rapid plastic or metal SLS prototypes with complex shapes that closely resemble injection-molded parts.

Advantage

SLS prototyping techniques allow prototypes to be made with material properties closer to that of injection molded pieces.

In addition, SLS has the capability to make metal prototype parts, where metallic powder is used in the laser sintering process. Building parts out of Somos 201 material gives a final SLS prototype made from a durable elastomer selective laser sintering material, ideal for bellows and gaskets.

Details in pictures:

Rapid prototype with plastic material

house appliance prototype